The hammer crusher is mainly suitable for the crushing of stone, chemical non-flammable, explosive and non-high toughness materials of various brittle materials. Large crushing ratio, high production efficiency is the advantage of hammer crusher, hammer crusher can do dry and wet two forms of crushing, hammer crusher is used to crush a variety of medium hardness abrasive materials, the strength of its compressive materials does not exceed 100MPa, and water content is less than 15%. Mainly used for coal, salt, chalk, gypsum, bricks, limestone, etc., can also be used to crush fiber structure, elastic materials, hammer crusher can not only be used for stone production line, sand production line, but also in the mineral processing production line to replace the cone crusher. Hammer crusher can be mainly divided into horizontal crushing, and vertical crushing two, customized for different use requirements, a wide range of use, in mineral processing, construction, chemical, waste reuse and other industries of application. Hammer Crusher is suitable to crush all kinds of brittle materials, like coal, coal ore, coke, slag, red sandstone, shale, loose limestone, etc.

1. Description:

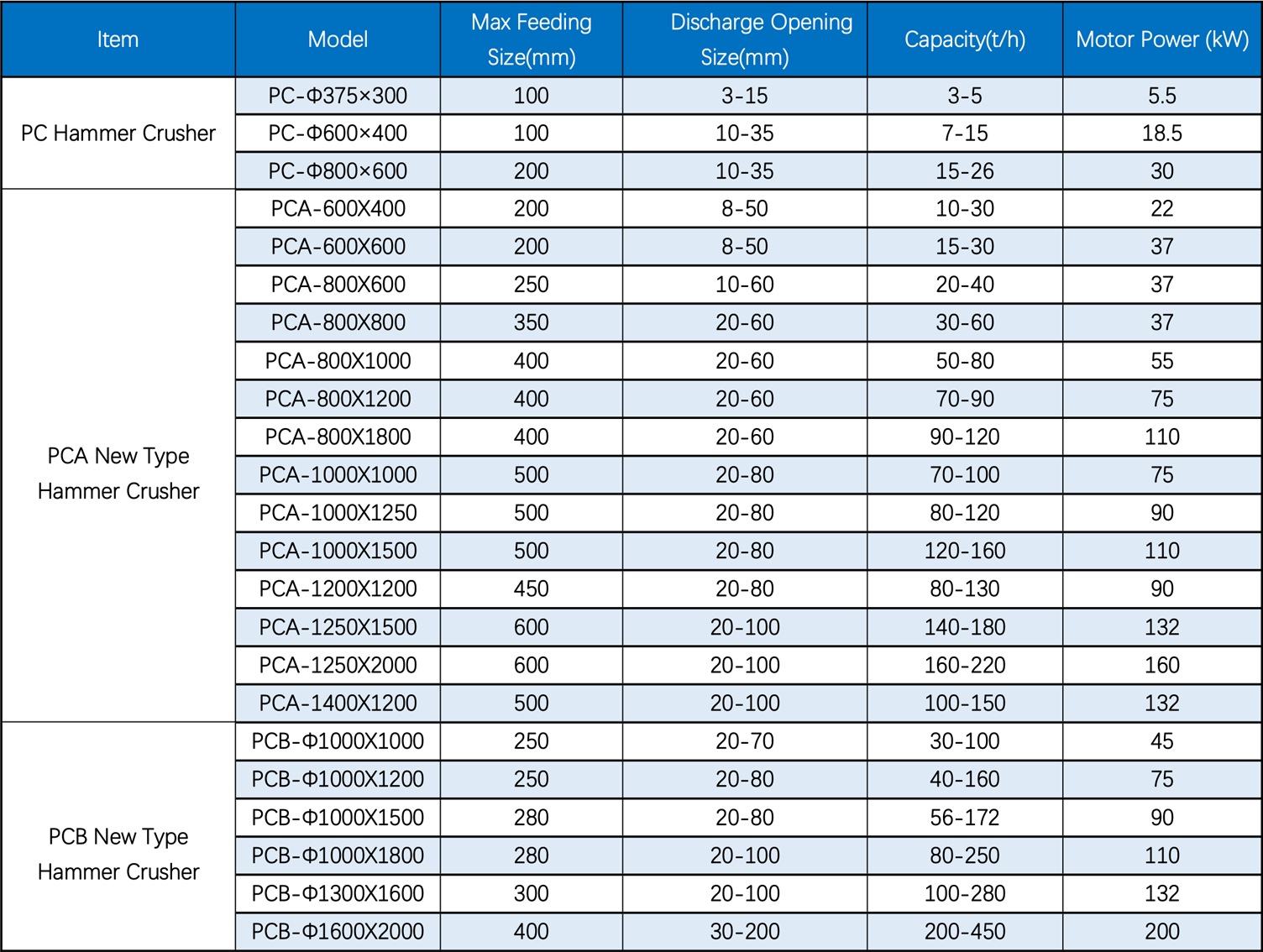

PC crushers were developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and Petroleum & Chemical industries.The capacity of our hammer crusher varies from 8~80 t/h. And the weight of our hammer crusher varies from 0.8~6.5 ton.

2. Working Principle:

PC crusher is composed of machine box, rotor, hammer, impacting lining board and screen board. According to the requirement of the customers, this equipment can adjust the gap between the grating bars to change the discharging granularity. PC crusher crushes material by impacting it against a rotating hammer, by the collisions between high-speed hammer and material.Then the material is forced against a rugged solid plate called a “breaker plate” which further degrades the particle size. Finally, the material is forced over a discharge grate by the hammers.

Note:

1. The voltage and motor power supply can be selected by the customer’s specific requirements.

2. The crusher capacity can be influenced by the material composition and output size.

We provide Customized Machines. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Send your inquiry for further information.

Specialize in the machines and solutions to the solid material size reduction & recycling

Copyright © 2023 Zibo United Tech Machinery Co., Ltd.