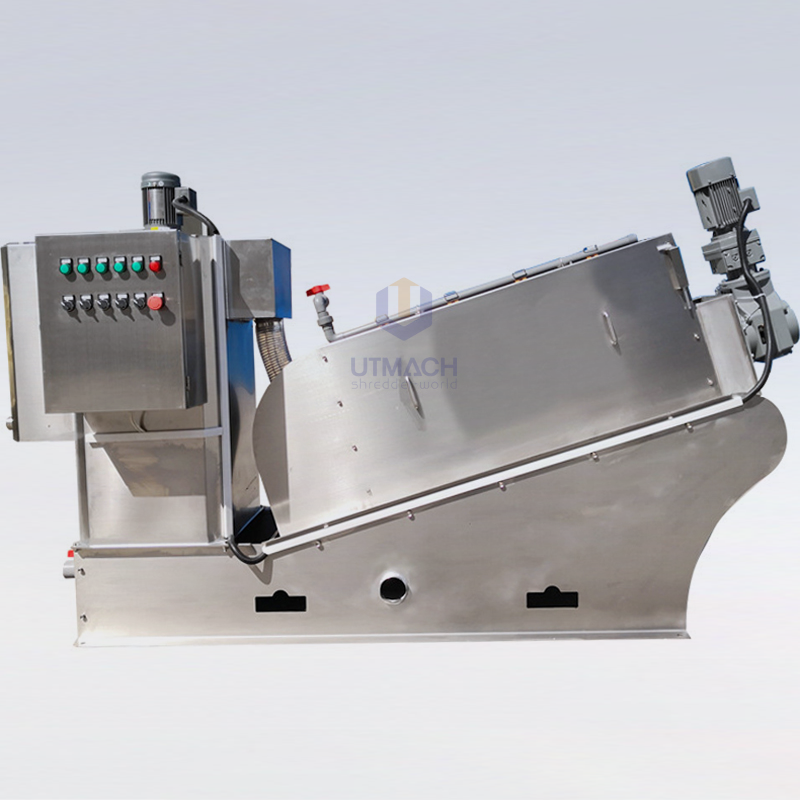

The stacked screw sludge dewatering machine from United Tech Machinery uses the principle of screw extrusion, through the strong extrusion force generated by the change of screw diameter and pitch, and the tiny gap between the moving ring and the fixed ring, the sludge can be squeezed and dewatered. It is a new type of solid-liquid separation equipment.

The stacked screw sludge dewatering machine from United Tech Machinery uses the principle of screw extrusion, through the strong extrusion force generated by the change of screw diameter and pitch, and the tiny gap between the moving ring and the fixed ring, the sludge can be squeezed and dewatered. It is a new type of solid-liquid separation equipment.

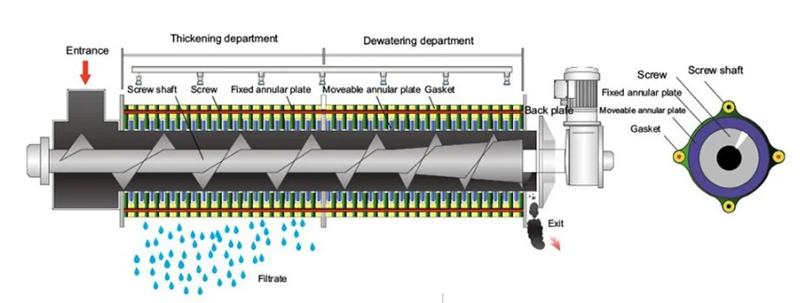

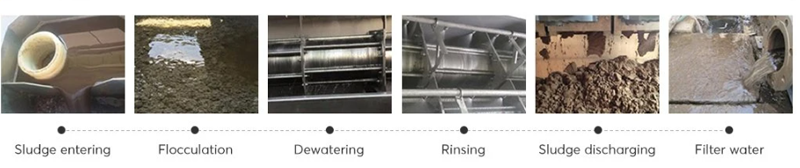

Working principle: The main body of the stacked screw sludge dewatering machine is composed of multiple fixed rings and floating rings, and the spiral shaft penetrates the filtering device formed therein. The front section is the thickening section, and the rear section is the dewatering section. The sludge thickening and squeezing and dewatering are completed in one drum, replacing the traditional filter cloth and centrifugal filtration methods with a unique and subtle filter body mode.

Dehydration principle: After the sludge is concentrated by gravity in the thickening section, it is transported to the dewatering section. As the filter gap and pitch gradually become smaller, and the back pressure plate is blocked, a great internal pressure is generated and the volume is continuously reduced. , To achieve the purpose of full dehydration.

Advantages:

Note:

Note:

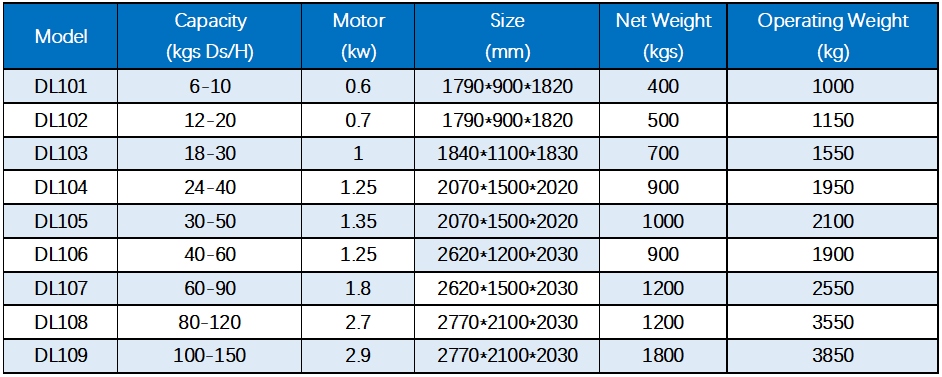

1. The voltage about the power supply can be selected by the customer’s specific requirements.

2. The capacity can be influenced by the material composition and output size.

3. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Send your inquiry for further information.

Specialize in the machines and solutions to the solid material size reduction & recycling

Copyright © 2023 Zibo United Tech Machinery Co., Ltd.