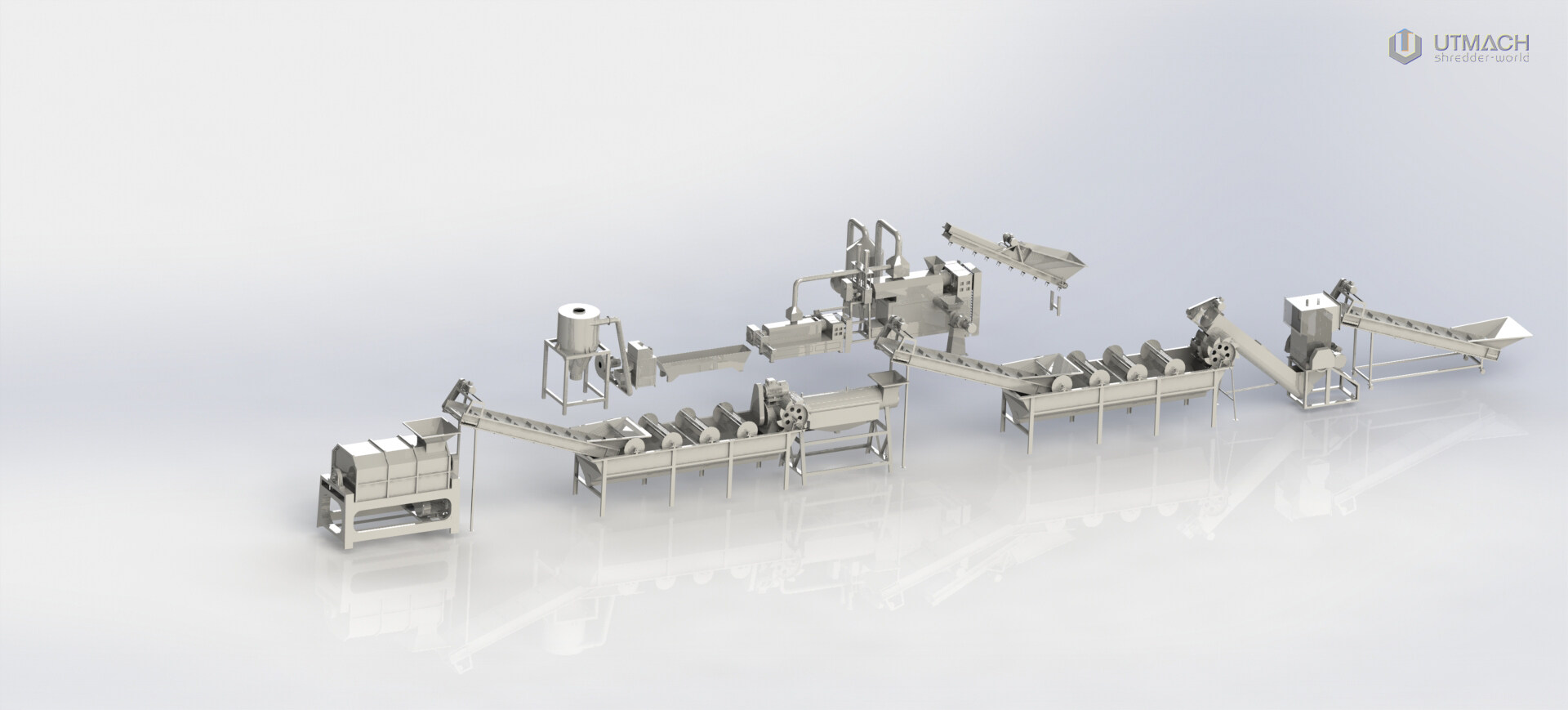

PP PE Film Recycling Line is widely used for recycling and processing of PP / PE / PA waste plastic film, PP / PE plastic waste mixture, waste PP woven bag (cement bag, space bag, snake skin bag), PP / PE plastic bag, domestic waste plastic, PE plastic garbage bag, waste agricultural film mulching film, industrial packaging film, industrial waste film, domestic waste oil film, service packaging film, shopping bag film, winding film, stretching film, etc. The yield can reach 300-3000 kg / h.