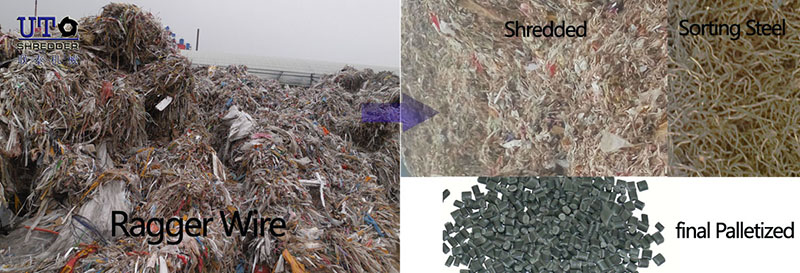

Ragger wires, also known as “pulper tails” and “pulper ropes”, are reject secondary raw materials that are created when waste paper is recycled. Ragger wires consists of the plastic trimmings, staples, tape, labels and baling wire found in baled post-consumer paper waste. It is made up of approximately 45% steel and 55% post consumer waste and must be removed from the pulper.

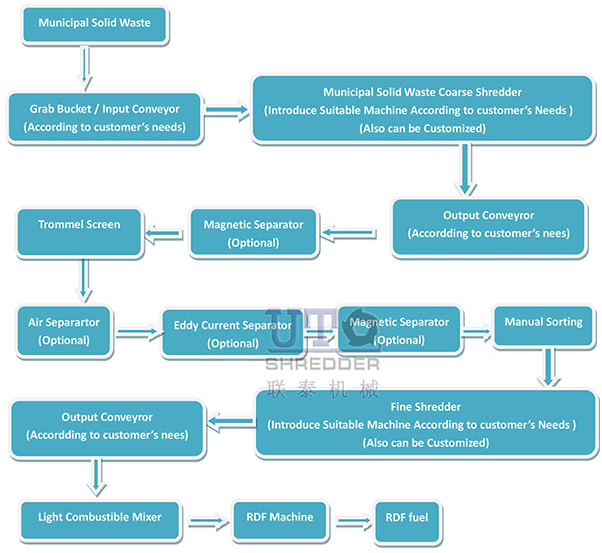

With Zibo United Tech Machinery’s purpose-built ragger wire recycling systems, this tough material can now be recycled and material separated, through shredding and subsequent separation of metals, plastics, and stones, etc. Residual waste becomes alternative fuel. In this way, the paper mill plants can save landfill space, reduce disposal costs, and generate revenue instead of waste.