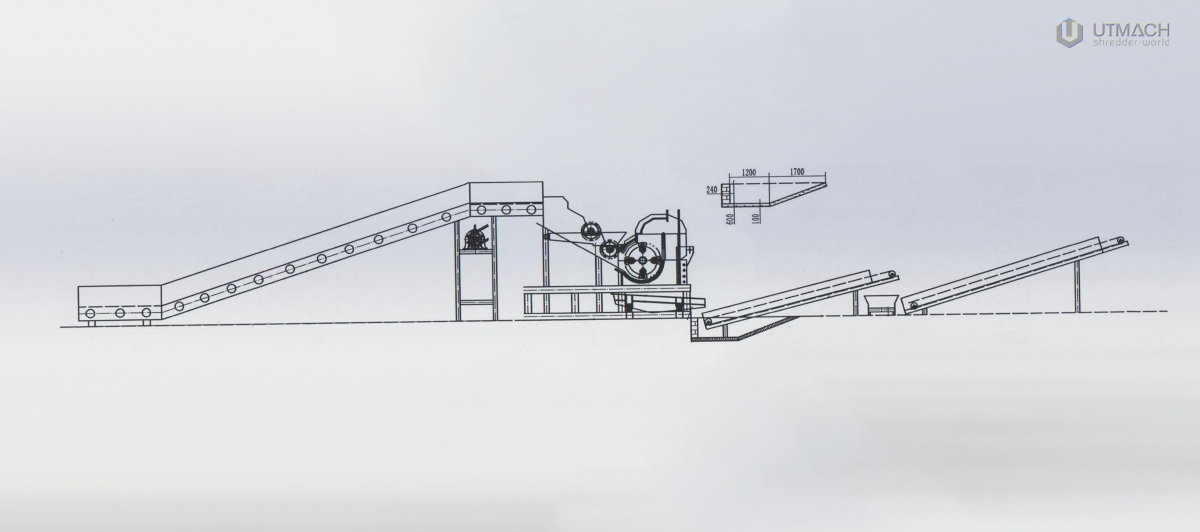

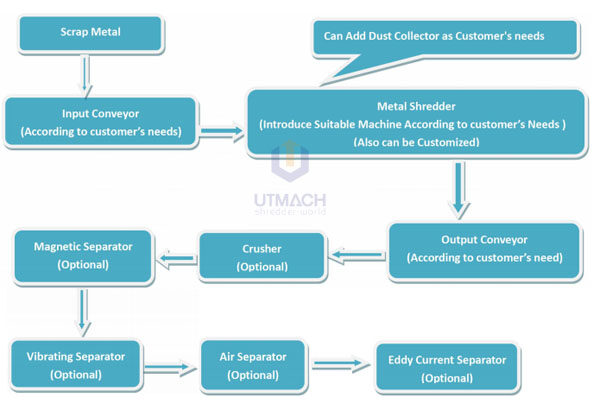

Scrap metal crushing line, which belongs to the scrap metal recycling production line equipment, is used for the crushing and processing of large volume scrap steel materials, various metal materials. Shredder production line is double star machinery specializing in processing color steel tiles, scrap bicycles, cars, scrap aluminum raw aluminum and other kinds of life scrap scrap and in the thickness of 8 mm below all kinds of scrap steel crushing.