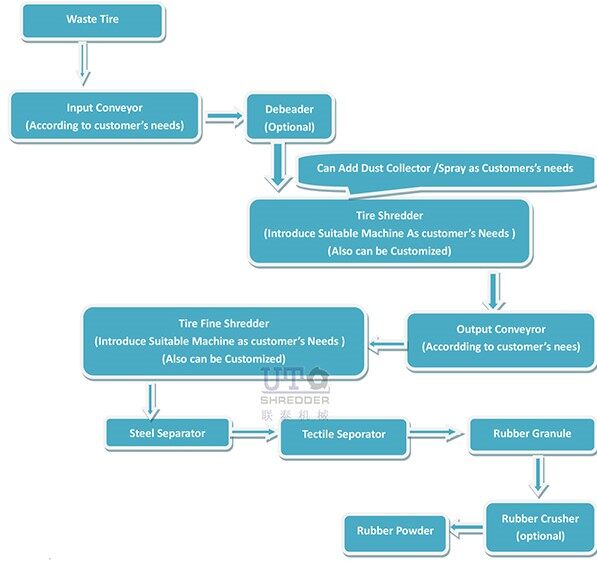

The tire shredding & recycing line is designed for different types of scrap tires from small cars, light commercial vehicles, trucks and construction machinery, etc. The recycling process includes crushing and processing, steel wire and fiber separation to produce pure rubber granules and powder.

The tire crushing and recycling line adopts modular design, which can add or reduce the production steps on its basis to enhance the flexibility of the line.